Sm:YAG–Excellent inhibition of ASE

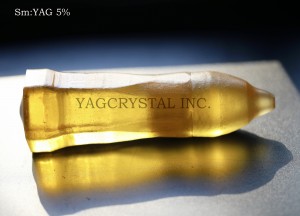

Laser crystal Sm:YAG is composed of the rare earth elements yttrium (Y) and samarium (Sm), as well as aluminum (Al) and oxygen (O). The process of producing such crystals involves the preparation of materials and the growth of crystals. First, prepare the materials. This mixture is then placed in a high-temperature furnace and sintered under specific temperature and atmosphere conditions. Finally, the desired Sm:YAG crystal was obtained.

Secondly, the growth of crystals. In this method, the mixture is melted and charged into a quartz furnace. Then, a slender crystal rod is pulled out from the quartz furnace, and the temperature gradient and pulling speed are controlled under appropriate conditions to make the crystal grow slowly, and finally the desired Sm:YAG crystal is obtained. Laser crystal Sm:YAG has many wide application scenarios. The following are some of the typical applications:

1.Laser processing: Because laser crystal Sm:YAG has high laser conversion efficiency and short laser pulse width, it is widely used in the field of laser processing. It can be used in a variety of material processing processes such as cutting, drilling, welding and surface treatment.

2.Medical field: Laser crystal Sm:YAG can be used for laser treatments, such as laser surgery and laser skin reshaping. It can be used in telescopes, laser lenses and lighting equipment.

3.Optical communication: Laser crystal Sm:YAG can be used as fiber amplifier in optical communication systems. It can enhance the strength and stability of optical signals, improve communication efficiency and transmission distance.

4.Scientific research: Laser crystal Sm:YAG can be used for laser experiments and physical research in the laboratory. Its high laser efficiency and short pulse width make it ideal for studying laser-material interactions, optical measurements and spectral analysis.