Reflect Mirrors– That Work Using The Laws Of Reflection

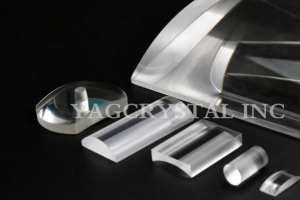

Product Description

A mirror is an optical component that works using the laws of reflection. Mirrors can be divided into plane mirrors, spherical mirrors and aspheric mirrors according to their shapes; according to the degree of reflection, they can be divided into total reflection mirrors and semi-transparent mirrors (also known as beam splitters).

In the past, when manufacturing reflectors, glass was often plated with silver. Its standard manufacturing process is: after vacuum evaporation of aluminum on a highly polished substrate, it is then plated with silicon monoxide or magnesium fluoride. In special applications, losses due to metals can be replaced by multilayer dielectric films.

Because the law of reflection has nothing to do with the frequency of light, this kind of component has a wide operating frequency band, which can reach the ultraviolet and infrared regions of the visible light spectrum, so its application range is becoming wider and wider. On the back of the optical glass, a metal silver (or aluminum) film is coated by vacuum coating to reflect the incident light.

The use of a reflector with a high reflectance can double the output power of the laser; and it is reflected by the first reflective surface, and the reflected image is not distorted and has no ghosting, which is the effect of front surface reflection. If an ordinary reflector is used as the second reflective surface, not only the reflectivity is low, there is no selectivity to the wavelength, but also it is easy to produce double images. And the use of coated film mirror, the image obtained is not only high brightness, but also accurate and without deviation, the picture quality is clearer, and the color is more realistic. Front surface mirrors are widely used for optical high-fidelity scanning reflection imaging.