Prisms Glued–The Commonly Used Lens Gluing Method

Product Description

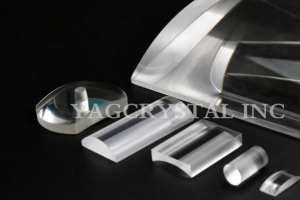

The commonly used lens gluing method is the optical glue gluing method, which is quickly glued under the action of ultraviolet rays. Often two or more lens sheets are glued together: two convex lenses and concave lenses with opposite R values and the same outer diameter are glued together with glue. Glue, and then superimpose the glued surface of the convex lens and the glued surface of the concave lens. Before the UV glue is cured, the eccentricity of the lens is detected by an optical detection instrument such as an eccentricity meter/centrometer/centering meter, and then pre-cured by strong UV irradiation of a UVLED point light source. , and finally put into the UVLED curing box (UVLED surface light source can also be used), and the weak ultraviolet light is irradiated for a long time until the glue is completely cured, and the two lenses are firmly glued together.

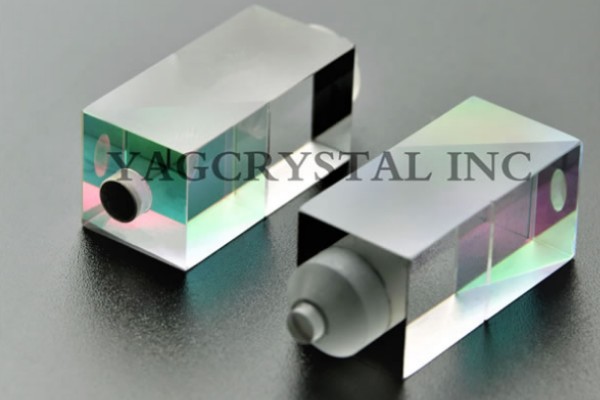

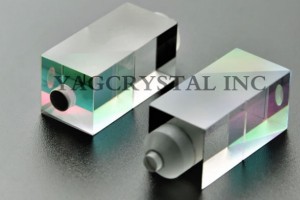

The gluing of optical prisms is mainly to allow optical components to improve the image quality of the optical system, reduce light energy loss, increase imaging clarity, protect the scale surface, and further optimize the processing process to meet the design requirements.

The gluing of optical prisms is mainly based on the use of optical industry standard glue (colorless and transparent, with a transmittance greater than 90% in the specified optical range). Optical bonding on optical glass surfaces. Widely used in bonding lenses, prisms, mirrors and terminating or splicing optical fibers in military, aerospace and industrial optics. Meets MIL-A-3920 military standard for optical bonding materials.

Features

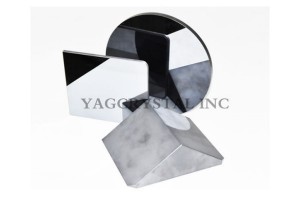

Optical prism In order to ensure the optical and mechanical properties of the optical parts obtained by gluing, the gluing layer should meet the following requirements:

1. Transparency: colorless, no bubbles, no fuzz, dust particles, watermarks and oil mist, etc.

2. The glued parts should have sufficient mechanical strength, and the glue layer should be firm without internal stress.

3. There should be no surface deformation, and it has sufficient stability against the influence of temperature, humidity and organic solvents.

4. Guarantee the parallel difference and waiting thickness difference of the cemented prism, ensure the center error of the cemented lens, and ensure the surface accuracy of the cemented part.