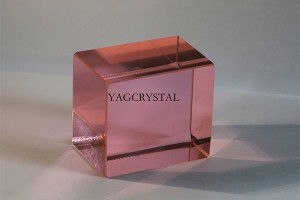

Nd:YAG+YAG一Multi-segment bonded laser crystal

The bonding process of Nd:YAG and YAG crystals is an important step in the preparation of laser crystals.

First, high-purity oxide raw materials such as aluminum oxide and yttrium oxide, as well as an appropriate amount of doping ions (such as neodymium ions) are selected and mixed evenly. Then, the mixture is heated to a high temperature to melt it into a liquid state. In this process, the temperature and atmosphere need to be strictly controlled to ensure the purity and chemical composition of the raw materials.

Next, the molten raw materials are gradually cooled and crystallized into block crystals through crystal growth technology. In this process, the growth rate and temperature gradient of the crystal need to be controlled to obtain high-quality crystals. For Nd:YAG crystals, it is also necessary to ensure the uniform distribution of neodymium ions and the appropriate doping concentration.

Then the crystal is shaped and optically surface treated to obtain the desired crystal shape and optical properties. In this process, cutting, polishing and other processes are required to ensure that the surface quality and optical properties of the crystal meet the design requirements.

In particular, the surface shape will completely affect the quality of the bonding surface. After everything is completed, the bonded crystals need to be placed in a hot bonding furnace. Through the high temperature of 1300℃, the molecules between the two ends of the crystals can penetrate each other, making the bonding surface more solid.

Contact Us

C01, Building 3, Screen Core Intelligent Manufacturing Headquarters Base, Shuangliu, Chengdu

There are many variations

There are many variations of passages of Lorem Ipsum available, but the majority have suffered alteration in some form,

by injected humour, or randomised words which don't look even slightly believable