Cr4+:YAG –An Ideal Material For Passive Q-switching

Product Description

Crystal Passive Q-switch is preferred for simplicity of manufacturing and operation, low cost, and reduced system size and weight.

Cr4+:YAG is chemically stable, UV resistant and it is durable. Cr4+:YAG will operate over a wide range of temperatures and conditions.

The good thermal conductivity of Cr4+:YAG is well suited for high average power applications.

Excellent results have been demonstrated using Cr4+:YAG as a passive Q-switch for Nd:YAG lasers. The saturation fluence was measured to be approximately 0.5 J/cm2. The slow recovery time of 8.5 µs, as compared to dyes, is useful for the suppression of mode locking.

Q-switched pulsewidths of 7 to 70 ns and repetition rates of up to 30 Hz have been achieved. Laser Damage Threshold tests showed AR coated Cr4+:YAG passive Q-switches exceeded 500 MW/cm2.

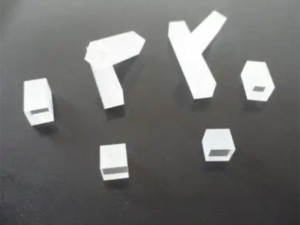

The optical quality and homogeneity of Cr4+:YAG is excellent. To minimise insertion loss the crystals are AR coated. Cr4+:YAG crystals are offered with a standard diameter, and a range of optical densities and lengths to match your specifications.

It also can be used to bonding with Nd:YAG and Nd,Ce:YAG ,casual size such as D5*(85+5)

Advantages Of Cr4+:YAG

● High chemical stability and reliability

● Being easy to be operated

● High damage threshold (>500MW/cm2)

● As high power, solid state and compact passive Q-Switch

● Long life time and good thermal conductivity

Basic Properties

| Product Name | Cr4+:Y3Al5O12 |

| Crystal Structure | Cubic |

| Dopant Level | 0.5mol-3mol% |

| Moh Hardness | 8.5 |

| Refractive Index | 1.82@1064nm |

| Orientation | < 100>within5°orwithin5° |

| Initial absorption coefficient | 0.1~8.5cm@1064nm |

| Initial transmittance | 3%~98% |

Technical Parameters

| Size | 3~20mm, H×W:3×3~20×20mm Upon request of customer |

| Dimensional tolerances | Diameter:±0.05mm, length: ± 0.5mm |

| Barrel finish | Ground finish 400#Gmt |

| Parallelism | ≤ 20" |

| Perpendicularity | ≤ 15 ′ |

| Flatness | < λ/10 |

| Surface Quality | 20/10 (MIL-O-13830A) |

| Wavelength | 950 nm ~ 1100nm |

| AR Coating Reflectivity |

≤ 0.2% (@1064nm) |

| Damage threshold | ≥ 500MW/cm2 10ns 1Hz at 1064nm |

| Chamfer | <0.1 mm @ 45° |